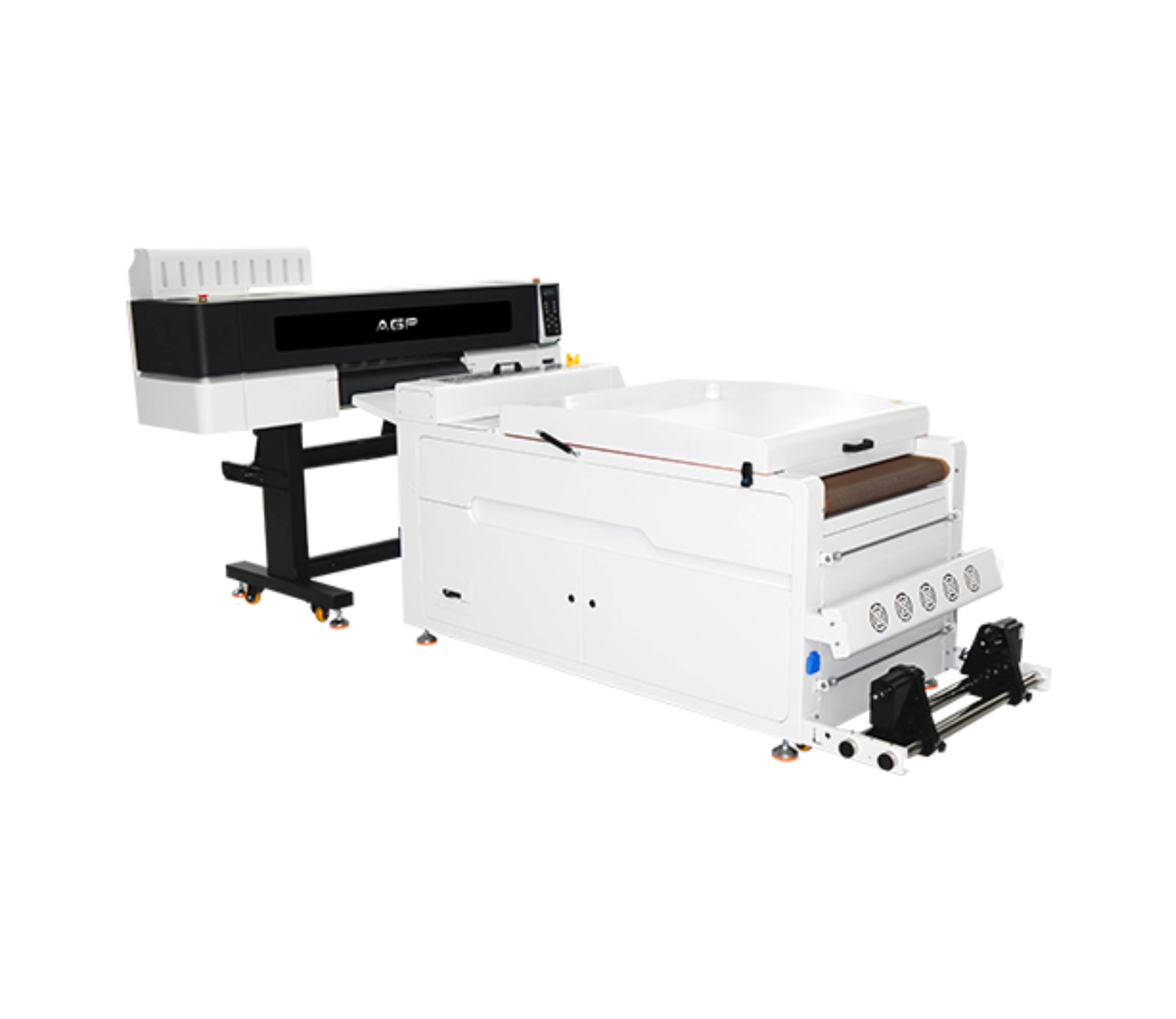

4 cabezales Epson I3200

AGP 4 Printheads

Descripción

Description

Maximum print width: 600 mm

Maximum speed: 23 m²/h

Compatible media: 620-mm PET film

Number of printheads: 4

Software compatibility: Maintop / PhotoPrint / Riprint

Textile Compatibility/Rigid Fabrics:

100% Cotton

100% Polyester

Cotton/Polyester Blends

Lycra – Elastane

Fleece – Rustic – Jersey

Sports Fabrics

Dark, Light, and Brightly Colored Fabrics

Denim / Jean

TNT (Non-woven Fabric)

Leatherette and Some Flexible Synthetics

Maintenance

- Dust-Free Environment Keep the work environment dust-free to prevent it from affecting printing.

- Temperature and Humidity The machine should operate at a temperature of 25–30°C and a humidity of 40–60%.

- Platform Cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the Underside of the Printhead Move the carriage to the cleaning position, clean the underside of the printhead with a non-woven cloth dampened with cleaning fluid or distilled water, removing dirt from the printhead and surrounding areas.

Related Products

-

15 Epson I3200 printheads

- PRINTER 15 heads

- PRINTING SPEED 1 pass 610 m²/h

- PRINT WIDTH 1900 mm

- COMPATIBLE MEDIA Heat transfer paper

- COMPATIBILITY Win 7 (64 bit) / Win 10 (64 bit)

-

- Daily power-on (even if you don't print) Helps the inks circulate and prevents bubbles from forming or drying out in the heads.

- Automatic cleaning activated Let the equipment do its maintenance cycle. Do not interrupt it: it prolongs the life of the head.

- Keep the capping station, dampers, and wiper clean These consumables accumulate ink and lint. A weekly cleaning prevents stains and clogs.

- Control the ambient humidity Ideal: 45%–60%. Low humidity dries the ink; high humidity generates droplets on the paper.

- Check feed rollers and trays If they are dirty, they mark the paper or generate banding.

- Use the equipment at least 3–4 times per week Sublimation plotters need constant ink movement.

Max width: 1900mmSpeed: 610 m²/hMedia: Thermal Transfer PaperRequest a quote -

6 cabezales Epson I3200

- High Speed 6-printhead design; maximum achievable speed is 32 m²/h.

- White-Ink Circulation System Prevents white-ink clogging and ensures more stable printing.

- Robust Body Japanese steel guide rail; integrated high-strength stand.

- Built-in Air Purifier Powder agitator with fume-purification function, electronic cleaner, and oil-fume separation.

- Intelligent Printhead Plate Heating The head heats automatically according to temperature to achieve uniform printing.

- Smart Touchscreen Easier operation thanks to the touch control panel.

Compatibility: Standard PhotoPrint and others.

Maintenance- Dust-Free Environment Keep the work environment dust-free to prevent it from affecting printing.

- Temperature and Humidity The machine should operate at a temperature of **25-30°C** and with a humidity of **40-60%**.

- Platform Cleaning Keep the entire printer tidy and clean, removing dust from friction areas.

- Cleaning the Underside of the Printhead Move the carriage to the cleaning position, clean the underside of the printhead with a **non-woven cloth dampened with cleaning fluid or distilled water**, removing dirt from the printhead and surrounding areas.

Max width: 600mmSpeed: 36 m2/hMedia: Pet film 600Request a quote -

4 cabezales Epson I3200

- HIGH-RESOLUTION PRINT HEAD 4 Epson I3200-A1 print heads, 2-pass speed can reach up to 150㎡/h.

- HIGH-END SOFTWARE Using international high-end software, the drawing is more realistic.

- INTELLIGENT LACK OF INK ALARM Reduces the tediousness of frequently checking the remaining ink quantity, and at the same time, reminds you to add ink in time to ensure the continuity of the printing job.

- USE OF ADVANCED CAPPING STATION Equipped with an advanced intelligent print head cleaning and moisturizing device, which provides safe and convenient maintenance and cleaning functions, with simpler operation and upkeep.

- INTELLIGENT MIST PRINTING AND VSDT PRINTING The unique intelligent two-dimensional mist and wave-mist function, along with VSDT variable droplet technology, significantly improves the printing quality.

- STABLE MEDIA FEEDING AND TAKE-UP SYSTEM Convenient and fast, printing media is quickly stored, equipped with automatic paper measurement and anti-rubbing function; if consumables are deformed, the printing automatically stops to prevent scratching the print head.

- SPECIALLY DESIGNED CARRIAGE The position of the print head can be adjusted according to different printing media and anti-collision devices on both ends to give the print head more comprehensive safety protection.

- LEADSHINE CHINESE MOTOR The Leadshine two-way brushless motor has higher precision, smaller length error, and more stable performance.

- LARGE CAPACITY INK TANKS Four units of 3L large-capacity ink tanks provide ink independently and continuously, ensuring the long-term continuity of ink output.

- INTELLIGENT HOT AIR DRYER The intelligent drying system synchronizes with the printing, saving energy and reducing emissions. During the printing process, the temperature can be adjusted in real-time according to the situation.

- THK SILENCE GUIDE RAIL Uses the Japanese THK silent linear guide rail, which provides more stable movement and a longer service life.

- IGUS INK CHAIN FROM GERMANY High-quality IGUS ink chain imported from Germany, ensuring the good completion of the printing work.

- FLUORINATED RUBBER PINCH ROLLER The US fluorinated rubber pinch roller prevents static electricity from flying ink, prints more accurately, and reduces wrinkles.

- TWO-LEVEL INK SUPPLY SYSTEM Adopts a two-level ink supply system, with continuous printing for a long time to ensure the image output quality.

- COMPATIBILITY Win 7 / Win 8 / Win 10.

- Daily power-on (even if you don't print) Helps the inks circulate and prevents bubbles from forming or drying out in the heads.

- Automatic cleaning activated Let the equipment do its maintenance cycle. Do not interrupt it: it prolongs the life of the head.

- Keep the capping station, dampers, and wiper clean These consumables accumulate ink and lint. A weekly cleaning prevents stains and clogs.

- Control the ambient humidity Ideal: 45%–60%. Low humidity dries the ink; high humidity generates droplets on the paper.

- Check feed rollers and trays If they are dirty, they mark the paper or generate banding.

- Use the equipment at least 3–4 times per week Sublimation plotters need constant ink movement.

Max width: 1900mmSpeed: 150m2/hMedia: Transfer paperRequest a quote -

3 cabezales Epson I3200Maintenance

- Daily Cleaning of the Printhead Resting System Clean the wiper, cap station, and printhead rim every day. UV ink forms crusts that can clog nozzles if not removed promptly. Chiller (Water Cooler) Check

- X/Y/Z Axis Lubrication Apply appropriate lubricant every 1–2 weeks. Clean axes prevent vibrations and lines in the print.

- Avoid Ambient UV Light UV inks cure with light. Avoid exposing the print bed or cartridges to direct sunlight or external UV light.

- Flatbed Cleaning Keep the surface free of dust, adhesives, or material residue. Any residue can affect printhead height or damage the nozzle.

Ensure the chiller is functioning correctly.

✔️ Stable temperature (ideally 20–24°C)

✔️ Clean water and correct level

✔️ Change water every 30–45 days

Improper cooling can damage the printhead in minutes.

Vacuum System Check The vacuum should properly hold rigid parts. If suction is low, check the filters, hoses, and air intake.Max width: 600mmSpeed: 16 m2/hMedia: Glass, Acrylic, Tile / Ceramic Tile, Aluminum, iPhone Cases, Plastic, Foam Board, Wallpaper, Wall Art, Advertising Signage, Metal, Paper, Wood, MDF, Furniture, Cards, Marble, Golf Products, Gift and Promotional Items, Leather, PU, PMMA, PVC, PP, PE, PTFE, Plexiglass, Panels, Ceilings, Cardboard, Corrugated Cardboard, Chevron Panel, Fiberboard, Brick, Stone, Home Décor, Appliance Panels, Ceramic and Porcelain Tile, 3C Products, Oil Painting, Fresco, Sliding Doors, Photos, Marking and Signage, Exhibition / Trade Show Stands, etc.Request a quote